El nuevo filamento de soporte PLA EASY-OFF de Sakata 3D Filaments está fabricado a partir de la resina biodegradable PLA Ingeo 3D450, un material diseñado específicamente para la impresión 3D por NatureWorks, líder mundial en la fabricación de biopolímeros.

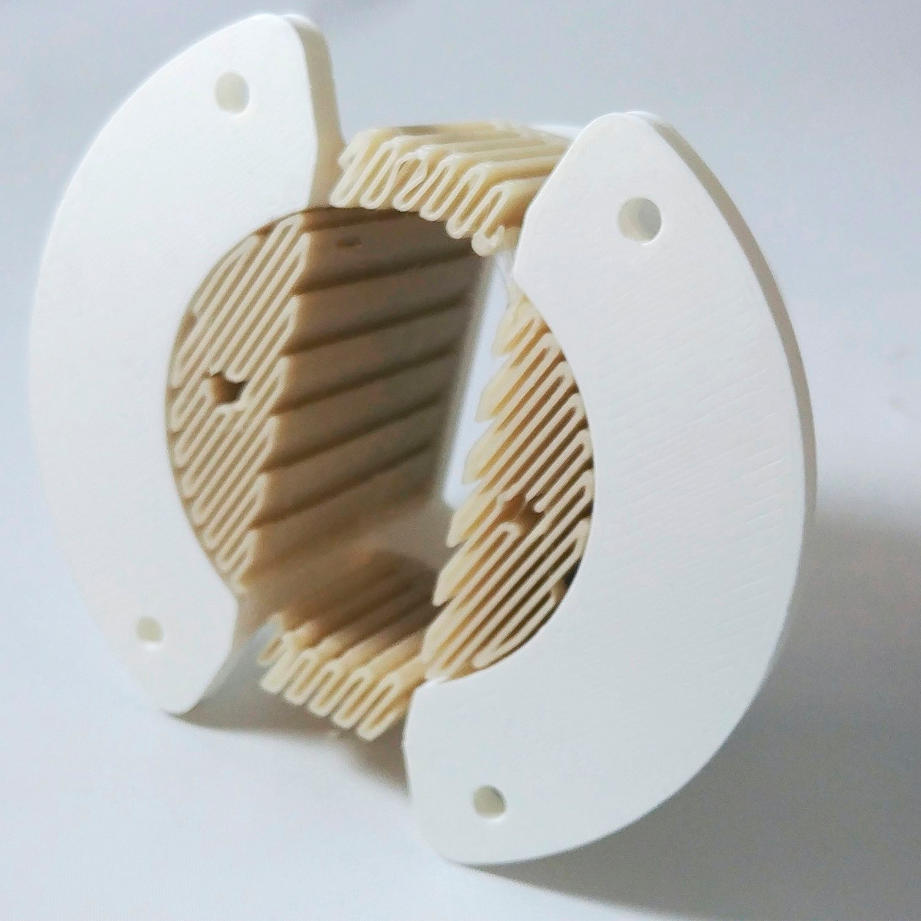

A diferencia de otros materiales de soporte, el filamento EASY-OFF permite obtener piezas industriales de elevada complejidad con acabados de alta calidad. Gracias a su fácil extracción, los tiempos de post-procesado son inferiores a los de otros materiales, mejorando de esta manera el rendimiento del proceso.

Este filamento está diseñado para trabajar con PLA 850 y PLA HR-870 a velocidades de hasta 100 mm/s sin sufrir deformaciones o problemas de refrigeración. No requiere de disolventes para su extracción. Posee una menor sensibilidad frente a la humedad que otros materiales de soporte (solubles) por lo que puede almacenarse durante un mayor periodo de tiempo sin que sus características se vean modificadas.

Aptos para la fabricación de moldes en arquitectura, fundición de metales por inversión, prototipado y joyerías.

![]() 200-220 ºC

200-220 ºC![]() >= 40 ºC

>= 40 ºC