Sakata 3D Filaments is the first Spanish manufacturer since 2018 to develop sustainable 3D printing materials for the environment, activating the concept of a circular economy and creating 3D printing filaments with the same mechanical and technical properties as the original raw material.

Since Sakata 3D Filaments was born, one of our commitments has been to the environment.

We started by finding an electricity distributor that could ensure a high percentage of renewable energy, implemented a filtering and recycling system for the water used in manufacturing, turn off equipment when not in use, adjust the air conditioning temperature, 98% of information or documentation exchanges with clients, suppliers and workers are done digitally reducing paper use.

This constant search for sustainability led us from the beginning to find an outlet for the printing material discarded in production, offering it another life and maintaining all the properties of the original pellets.

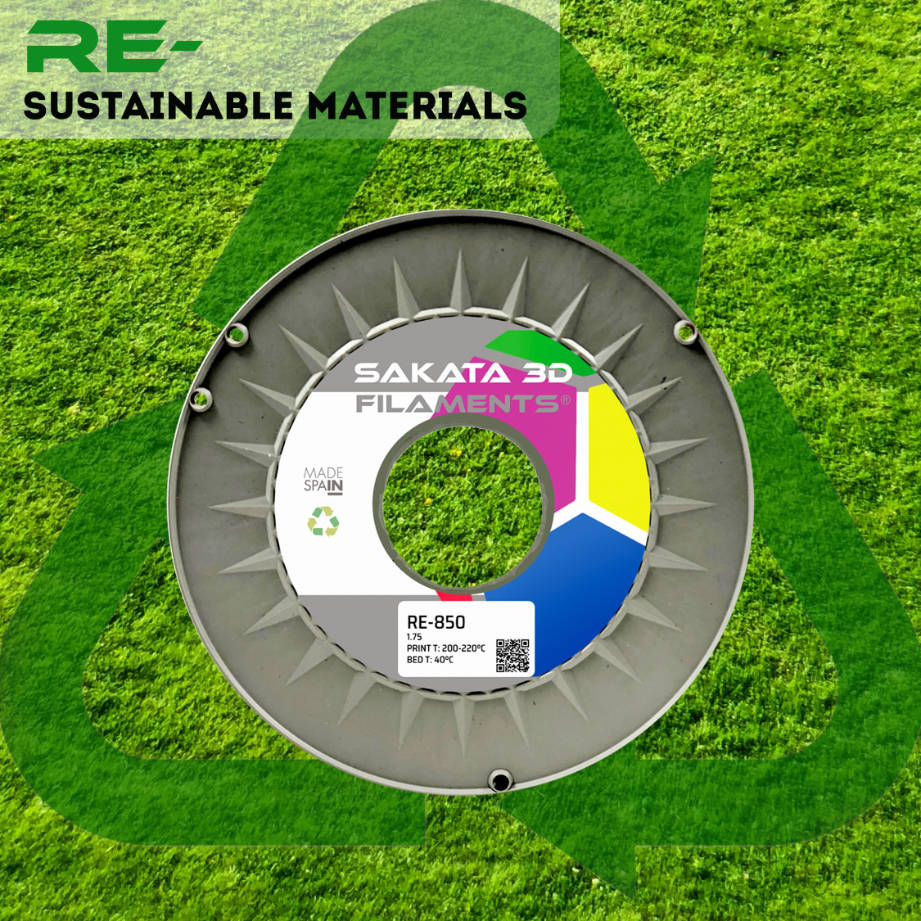

That's how the RE family idea was born, a family of sustainable materials, responsible for the environment and that favor a circular economy.

But the material was only the first element. The entire product had to be sustainable.

We then decided to bet on a new type of spool, obtained through the recycling of post-consumer and post-industrial materials.

In addition to giving a new function to plastics that would have ended up in landfills, contaminating and accumulating in what we now call "trashure", we have helped reduce the carbon footprint caused by the extraction of new crude oil and manufacturing of new spools.

We also bet on the use of raw cardboard packaging, without varnishes or screen printing, fully recyclable.

We were pioneers in Spain with the development of these sustainable materials starting with our recycled PLA 850 and HR-870 that we launched in 2018.

Thanks to the incredible acceptance by our customers, the RE family grew, being able to add new materials such as RE-PETG and RE-ABSE.

And thanks to having been pioneers in this circular economy, we have seen how other manufacturers have been inspired by the RE family of sustainable materials from Sakata 3D Filaments, developing recycled materials.

Investing so that new generations can enjoy a sustainable future and becoming aware that not only short-term benefits are important, have become a maxim in our company.

Our hope is that more and more companies join our vision and can be inspired by us to create their own sustainable materials.